Semester in Composites Materials

IMT Nord Europe has developed a range of programs provided in English.

International students get the opportunity to study semesters totally taught in English.

Evaluations are conducted at the end of each period with dedicated exams or project defense or report.

Admissions

Syllabus

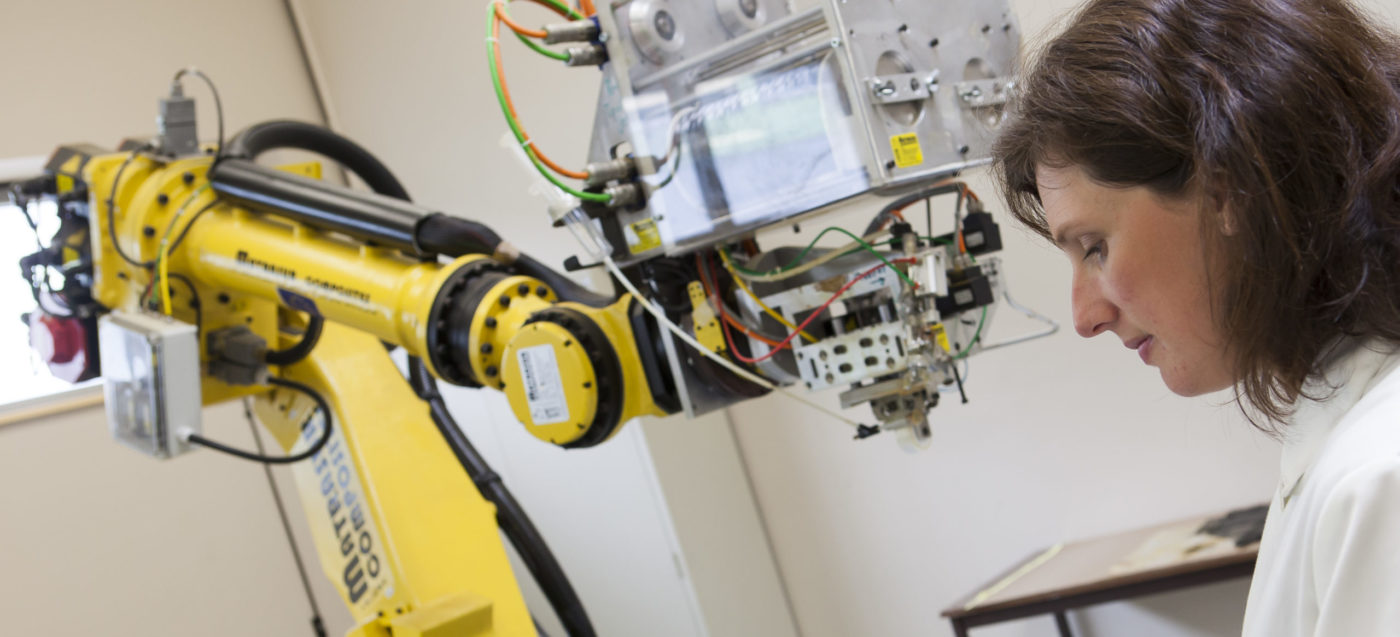

Objectives: The first period focuses on the study of polymers and composite materials, their components, characteristics, markets and their position with respect to other materials. Polymers and composites processes are described and detailed according to their field of application, costs and cycle times, the materials used and the types of parts produced in terms of size, shapes and expected performances. The process control parameters as well as the possible defects generated during manufacturing are studied, through lectures but also via practical work carried out on industrial scale production units available on the IMT Research Center technological platforms.

Skills: The objective for the students is to be able to justify which materials can be selected according to a foreseen application, and to select an adapted process.

Lectures:

- Polymers and polymeric structures

- Composite materials

- Sandwich structures

- Polymer processing

- Rheology

- Composite manufacturing processes

Objectives: In this module the knowledge required to conduct structure dimensioning for different markets (ground transportation, aerospace, civil engineering, sport and leisure industries) is presented, including elasticity principles and numerical methods (finite element analysis).

Direct application will be conducted through a project using a commercial FEA code.

Skills: at the end of this module, you will be able to use mechanical and material behavior laws and apply FEA modeling for designing purposes.

Lectures:

- Elasticity

- Finite element Analysis

- Autonomous and group project

Objectives: According to a precise scope given by the teaching team, find an innovative idea, and give it birth using functional analysis, CAD tools for design and first dimensioning. You will have access to the composite manufacturing lab and advanced 3D printing units to propose a prototype version of your work. Working alone, in pairs or in groups, a tutor will assist you all along the project.

Skills: this project will develop your personal skills, taking part into a project, standing to your opinions and work in groups. You will also have to take into account the different aspects of an innovative project, such as the market study, the functional analysis and the economical evaluation of the solution.

Objectives: The link between the multi-scale structures of composite laminates and their corresponding characteristics and mechanical properties at different length scales (scale of a reinforcing fibre, of an in-plane arrangement unidirectional fibres, and of a stack of unidirectional plies) is established during this period. The scheduled lectures provide an introduction to micromechanical homogenization approaches and simulation of the mechanical behaviour of composite parts, that requires taking into consideration the transition between these different length scales. The main design principles are addressed according to the failure criteria in the framework of the classical laminate theory. The theoretical aspects are complemented by both face-to-face and non-face-to-face practical work conducted in the form of guided projects. These projects are based on the one hand on the finite element method and on the other hand on experimental techniques of non-destructive testing.

Campus: Douai

Lectures:

- Composite materials characteristics (Lectures -12h)

- Mechanics of composites and sandwich structures (Lectures -12h and Lab Sessions -8h)

- Non-destructive techniques for composite materials characterization (Lectures -20h)

- Finite element analyses applied to composite mechanics (Lab Sessions -8h)

- Case study (Project -20h)

During the whole semester, students follow a weekly 2-hour French course (specific for international students), corresponding to 2 ECTS.